Electric Truck Depots Are Evolving: How 10 Fleets Grew Their BEV Populations

Run on Less – Electric DEPOT (RoL-E DEPOT) showed that it is possible to scale from one or two trucks at a fleet depot to 15, 20, 30 or more in four market segments including vans and step vans, medium-duty box trucks, terminal tractors, and heavy-duty tractors in regional haul.

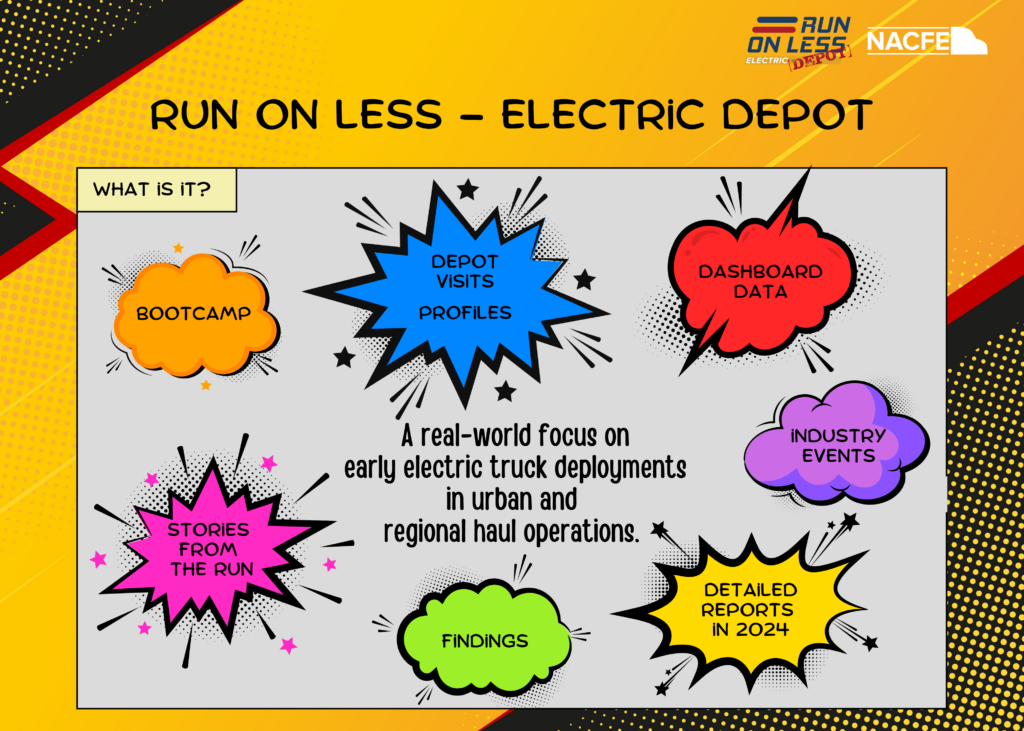

How It Worked

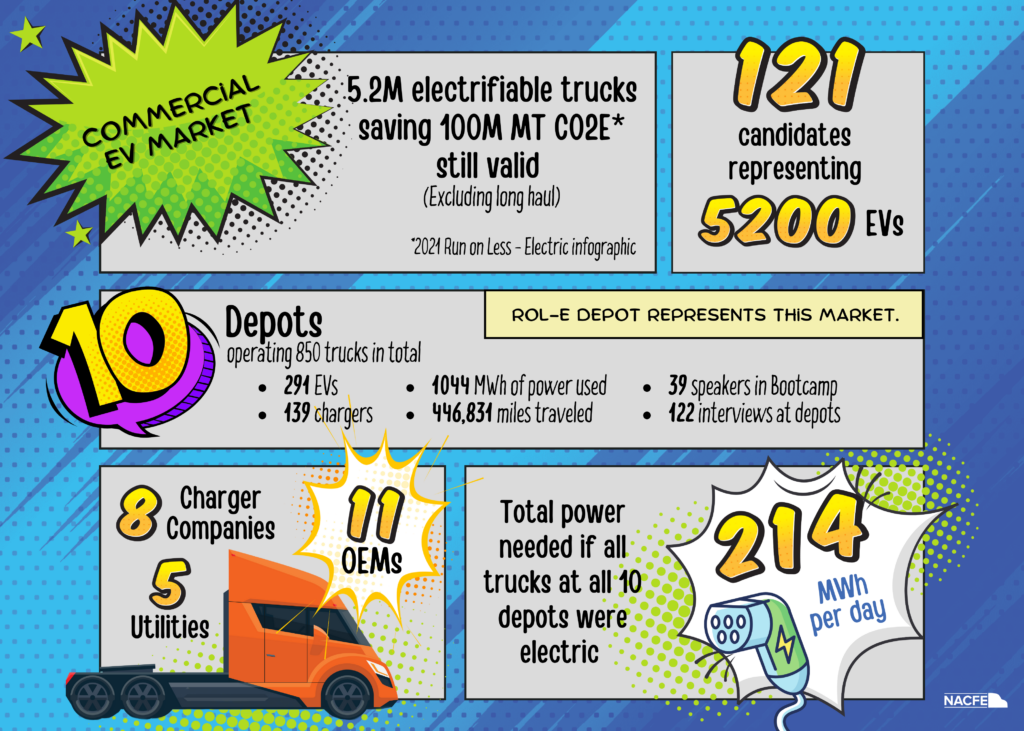

From a group of 121 candidates representing 5200 BEVs, NACFE selected 10 fleet depots to participate in the Run. NACFE wanted the best variety of locations throughout North America. This included a variety of OEM truck models, a variety of duty cycles, the number of BEVs at each location, a variety of charging systems, different charging duty cycles, different power consumption levels and different type of utilities.

There needed to be 15 or more electric trucks at the depot by May 2023 in order for NACFE staff to complete site visits. The depots had to be willing to share data and anecdotal information about their experience of adding BEVs in bigger numbers to their fleets. Fleets, OEMS, EVSE suppliers and utilities had to be willing to spend time supporting NACFE’s site visits and promotional efforts.

NACFE had hoped to select fleets across a wider geographic area, but the reality of BEV deployment resulted in eight fleet depots in California, one in New York and one in Canada.

The 10 fleets depots participated in the Run were:

- Frito-Lay operating two Ford E-Transit in Queens, New York.

- OK Produce operating an Orange EV e-TRIEVER and a Freightliner eCascadia in Fresno, California.

- Penske operating a Ford E-Transit, a Freightliner eCascadia, a GM BrightDrop ZEVO 600, and an International eMV in Ontario, California.

- PepsiCo Beverages operating three Tesla Semis in Sacramento, California.

- Performance Team Logistics operating two Volvo VNRs in Commerce, California.

- Purolator operating a Ford E-Transit and a Motiv EPIC in Richmond, British Columbia, Canada.

- Schneider operating two Freightliner eCascadias in South El Monte, California.

- UPS operating a Freightliner eCascadia and a Freightliner Custom Chassis Corporations MT50e in Compton, California.

- US Foods operating two Freightliner eCascadias in La Mirada, California.

- WattEV operating a BYD 8TT and a Nikola Tre BEV in Long Beach, California.

What Was Measured

All NACFE’s Run on Less events track and present data, and RoL-E DEPOT was no different. The homepage of the Run on Less website has a link to the RoL-E DEPOT dashboard, which was developed to capture and present data on the vehicles and depots that participated in the Run.

Findings

Initial findings which were developed halfway through the Run were validated by the data collected throughout the entire 18 days of the Run. NACFE expects this will give fleets confidence in moving toward wider deployment of battery electric vehicles.

One key finding was that the fleets in RoL-E DEPOT were a good representation of the current state of the trucking industry. A total of 850 trucks were operated out of the 10 depots of which 294 were BEVs. The depots had a total of 139 chargers and 1044 MWh of power were used as the trucks traveled 446,831 miles over the three weeks of the Run.

Another key finding was that small depots are ready for electrification now. NACFE defines a small energy depot as ones that require less than 10 MWh of power per day because of the small number of trucks and/or low number of miles those trucks travel in a day. There is less cost in energizing these depots.

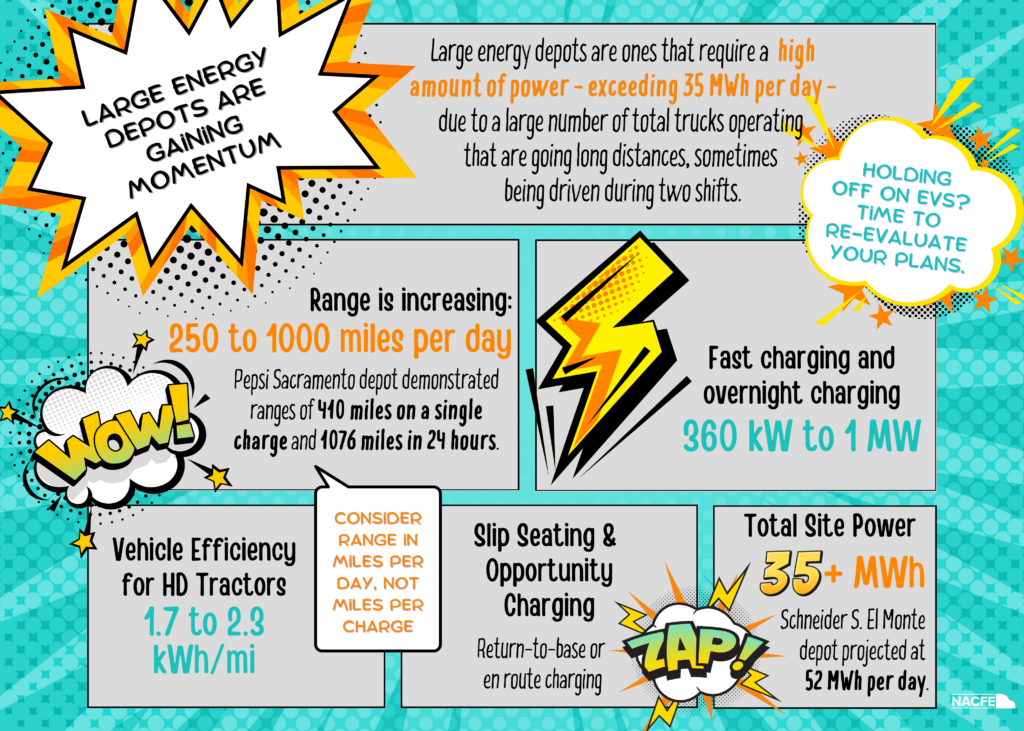

Electrification at large energy depots is gaining momentum. NACFE defines a large energy depot as one that requires a high amount of power typically exceeding 35 MWh of power per day because there are a large number of trucks operating out of the depot and the trucks are traveling longer distances. Sometimes the BEVs even are driven during two shifts.

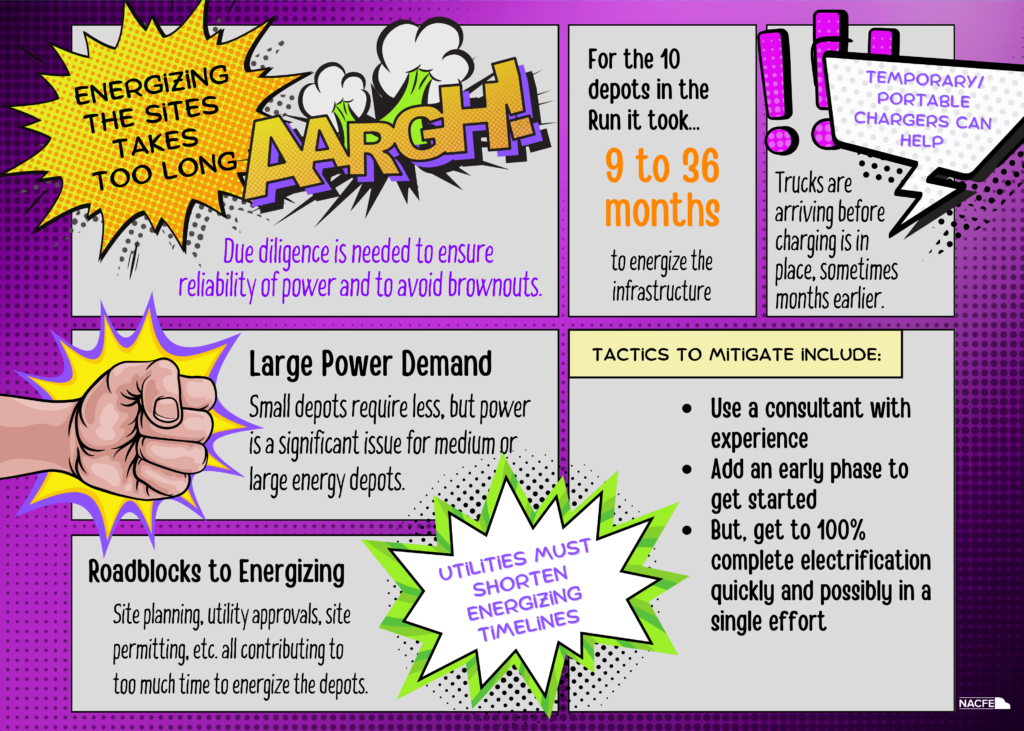

One challenge that was reinforced during the Run is that it’s still taking too long for power delivery and infrastructure to be installed, which is driving portable/temporary charging. It took 9 to 36 months to energize the infrastructure at the 10 depots that participated in RoL-E DEPOT.

NACFE also found that there have been big improvements in trucks and chargers since Run on Less – Electric in 2021. RoL-E DEPOT showed that the industry needs cost and weight reductions to improve the total cost of ownership and that range can be extended with multiple charges per shift at the depot and en route. NACFE also believes that diversity, passion, and capability of the people involved is helping to scale the adoption of electric trucks.

Infographic

This infographic illustrates NACFE’s findings from Run on Less – Electric DEPOT. Download individual images below, or download a PDF of the entire graphic.

An Industry Effort

Run on Less – Electric DEPOT could not have happened without the collaboration and cooperation of many people and organizations. NACFE is grateful to the participating fleets, drivers, OEMs, sponsors, members of the media, utilities, suppliers of chargers and charge management systems, governmental officials, non-governmental organizations, and RMI for their efforts in making this Run a success. A special thanks to all the people who went on camera to share their thoughts on the benefits and challenges of adding larger quantities of BEVs to fleet depots. NACFE and the entire trucking industry is grateful for you sharing what you learned with us.