Trailer Aerodynamics

“Data shows that trailer aerodynamic devices help fleets save fuel. The priority for device adoption is side skirts, rear devices and then gap.”

Adding aerodynamic devices such as nose cones, skirts, under body devices, tails, etc. to the generally boxy trailers can improve fuel efficiency. The higher the speed the more effective these devices become. An obstacle to their adoption is that most fleets have multiple trailers for each tractor limiting the miles driven per year and increasing the payback time.

There is significant data showing fuel savings for the various trailer aerodynamic devices. The priority for device adoption by fleets is skirts, tails, front, and then other devices. Devices have matured and will continue to improve. Skirts have become lighter, less expensive, and more robust improving their payback. Other devices are maturing but need continued development to improve their total cost of ownership. There are unique challenges with trailer aerodynamics. These include the trailer-to-tractor ratio, the fact that the purchaser of the aerodynamic device is not the one buying fuel, and the fact that some devices need driver intervention.

Decision-Making Tools

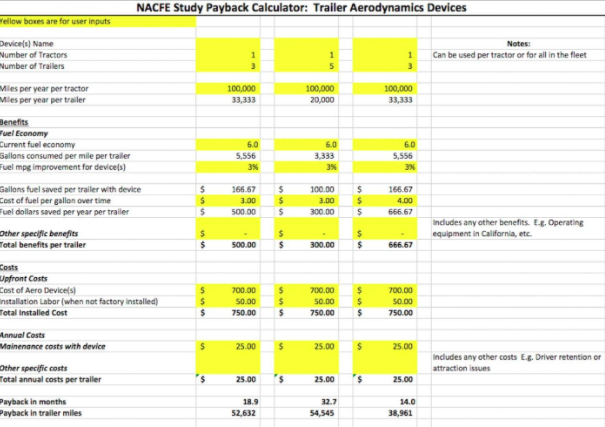

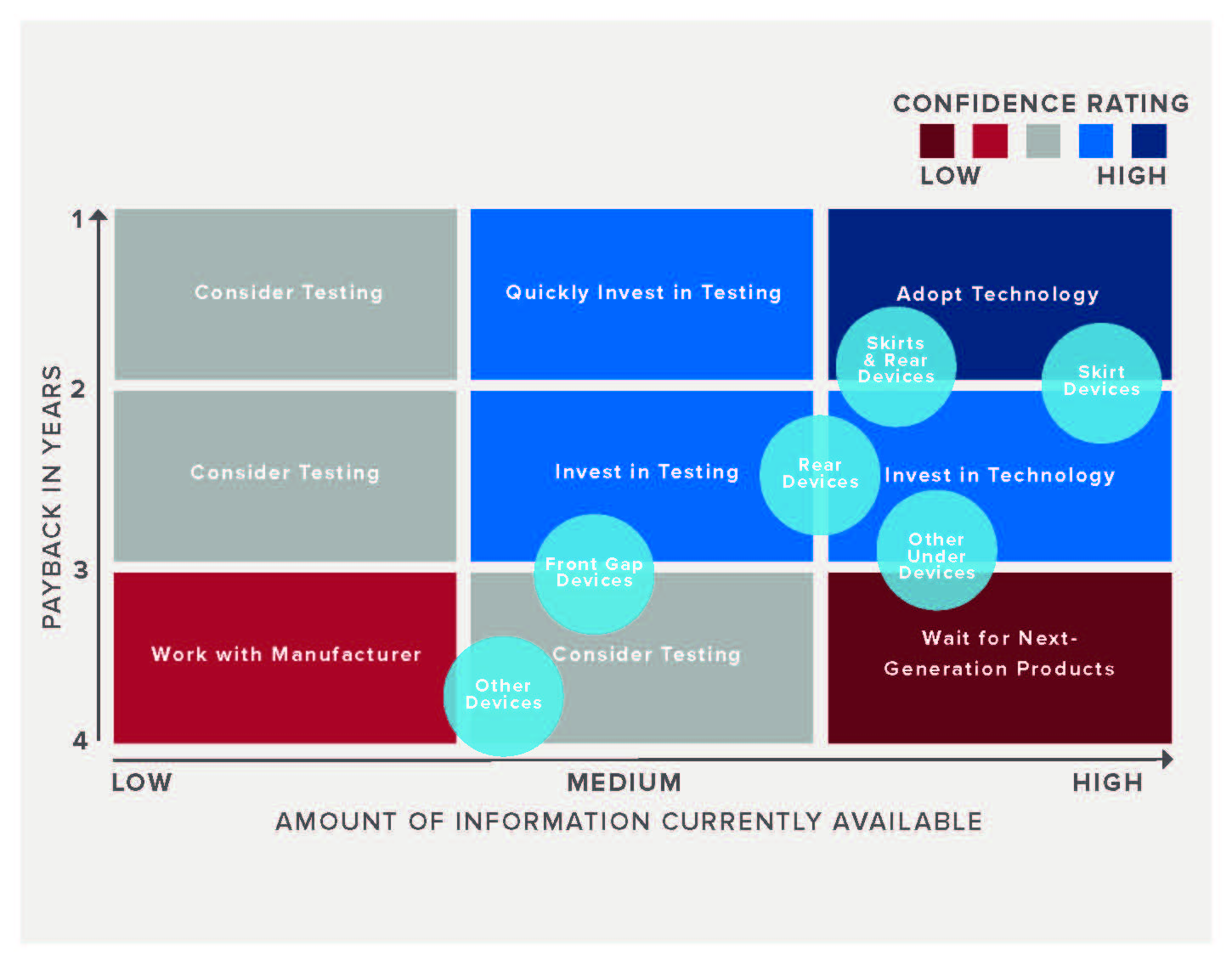

NACFE has developed several tools to help fleets make their decision about trailer aerodynamic devices.

• The Confidence Matrix, informs fleets of NACFE’s confidence in the technology being studied vs. the payback the fleet should expect to receive from the technology

• A simple payback calculator has been developed for aerodynamic devices

• An appendix of SmartWay verified trailer aerodynamic devices can be found at the end of the full Confidence Report