Idle Reduction

Historically, a large amount of operating time of a sleeper tractor-trailer engine was idling. This could be 45% or more, where the driver is sleeping, eating, working or relaxing in his or her vehicle when they are not driving.

Each year in the United States sleeper tractors burn millions of gallons of diesel fuel while idling. The average truck idles about 1,000 hours a year. This is costly, noisy, dirty and not efficient. A plethora of idle-reduction solutions have emerged including on board diesel and battery units, engine start stop, diesel heaters and driver training and incentives to drastically lower idling. Each, along with other complementary actions, have their benefits and challenges with respect to fuel and emissions reductions, upfront cost, maintenance costs, infrastructure, etc.

Decision-Making Tools

Our team produced top-line tools to assist fleets in making their idle-reduction technology choice:

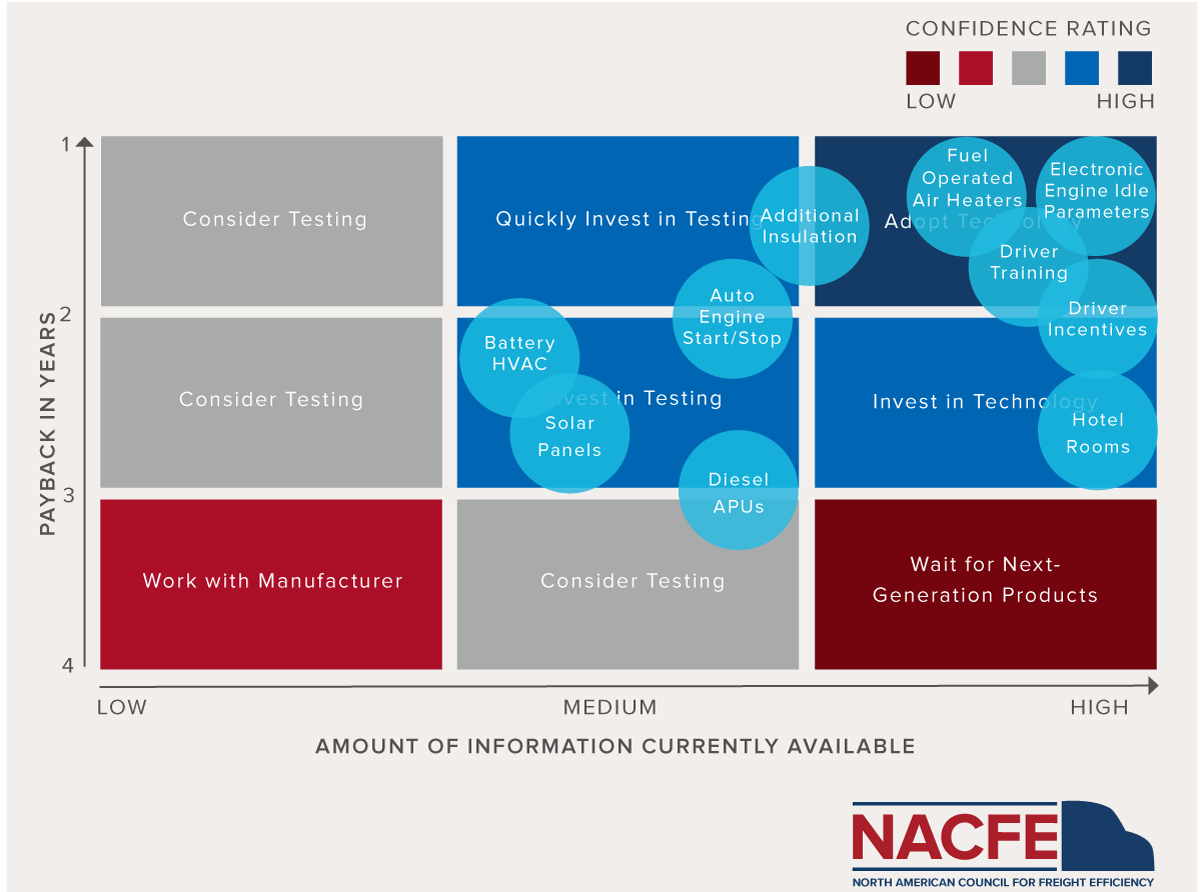

The confidence matrix summarizes the study findings and indicates NACFE’s confidence in the various idle-reduction technology solutions.

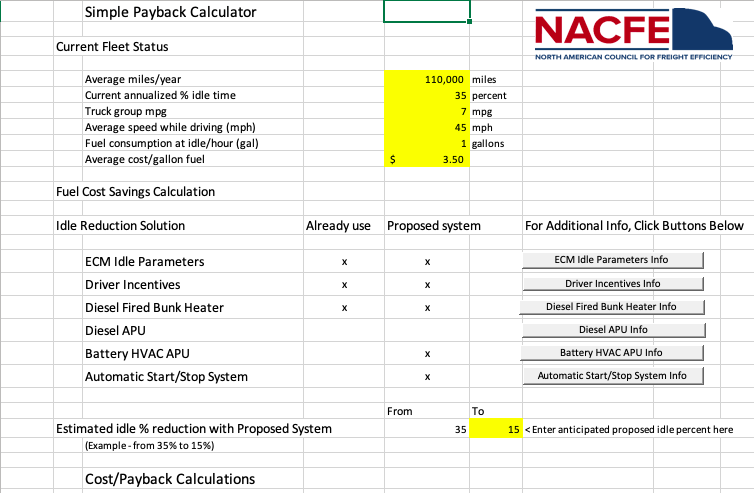

The Payback Calculator allows fleets to estimate the payback in months for various idle-technology solutions. Fleets input data into the form and the calculator uses the data along with the information gathered by the study team to quantify and benefits and consequences likely to be experienced by the fleet in terms of upfront costs and year-over-year costs.

In addition the report contains challenges and changes charts for each of the anchor technologies. The charts can be found in section 9 of the report.