Engine Downspeeding

Downspeeding is one of the primary powertrain-focused strategies for improving fuel economy in heavy-duty trucks necessitated by greenhouse gas emissions regulations.

With downspeeding the rear gear ratio is sped up in order to lower the speed of the engine, bringing fuel efficiency improvements. Downspeeding allows the engine to operate at the most efficient rpm while generating the minimal horsepower required to maintain a 65 mph cruise speed.

Benefits

Fuel Savings

Downspeeding can save 2% to 3% off of the fuel bill.

Improved Driveability

With downspeeding, the truck will have an AMT which results in smoother operation.

Reduced Noise

Due to the lower engine speed.

Challenges

Potential for Driveline Failure

Downsped axles, being less flexible, are much more sensitive to sudden shocks.

Greater Upfront Costs

Need to spec an automated transmission with a higher output torque capability, a certain clutch with a higher capacity damper, and higher torque driveshafts and rear axles.

Common Fleet Strategies

Downspeeding can be adopted in one of two configurations:

- A direct drive transmission and a fast axle ratio The fast axle ratio direct drive transmission specification is optimal in terms of friction and fuel consumption reduction, but given the potential for driveline failure some manufacturers only approve it for true line haul applications where the highest torque conditions occur infrequently.

- An overdrive transmission and somewhat slower rear axles. The somewhat slower axle ratio of an overdrive transmission spec subjects the transmission output, driveshafts, and axles to far less torque. This makes it appropriate for both line haul and regional and city delivery applications. An automated transmission should be spec’d on any downsped engine. If a manual transmission is selected, the engine’s torque response during clutch engagement must be specifically tailored to the drivetrain.

What People Are Saying

Drivers transitioning directly from a manual transmission to a downspeeding driveline must get used to not shifting and allowing the driveline to do the work. Of course, this probably is easier said than done for a driver who has upshifted, downshifted, and double-clutched for years. They must also adapt to the transmission shifting gears at engine rpms of approximately 1250 rpm instead of manual shifts at around 1800 rpm.” — John Moore, Volvo Trucks “An improvement of 3–6% is what you’ll see; I’m very comfortable predicting an improvement of 3%. When downspeeding is combined with other improvements in fuel economy-related aspects of design, fleets could reasonably be expected to see as much as a half mile per gallon.

– Aaron Peterson, Navistar

The trend toward engine downspeeding will continue to gain momentum as OEMs look for ways to further improve fuel economy.

— Andy Nieman, Dana Commercial Vehicle Technology

I hadn’t driven one of these new trucks in a few years and was amazed at how fun they are to drive! And it starts with how quiet they are.” — A major fleet manager “I was blown away by how it drove. In top gear, it would run down to 800–900 rpms, hanging in there very well. One advantage is that it’s very quiet, the engine is not roaring. Drivers like it. They worry about getting up to speed, and it does that okay. We’re not sure whether or not it does have the power to do the mountains, though.

— Phil Braker, Nussbaum Transportation

Decision-Making Tools

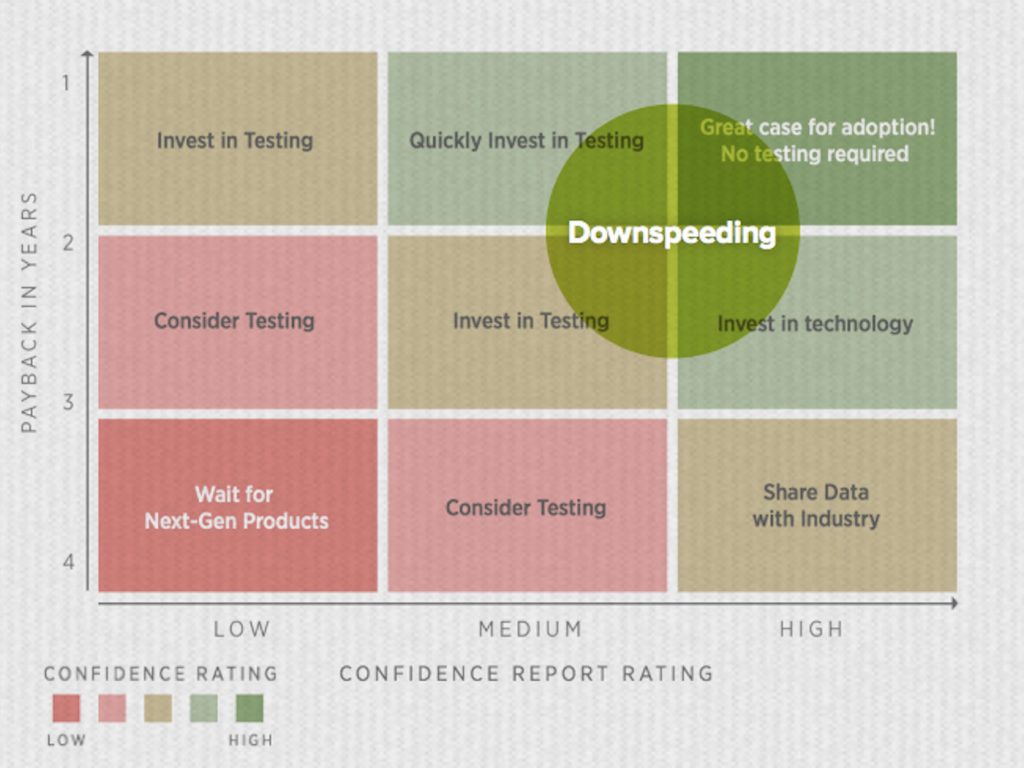

The study team developed a tool to help fleets in making their decision about electronically controlled transmissions. The Confidence Matrix is used to inform fleets of the study team’s confidence in the technology being studied vs. the payback a fleet should expect to receive from the technology.

Conclusions

- Downspeeding is an idea that has been around a long time, but recent complementary technologies have made it more attractive and practical.

- Fleets in long haul operation should consider downspeeding in their powertrain for improved fuel efficiency and driver satisfaction.

- Some manufacturers are already at work on aggressive downspeeding with rear axle ratios at 2.28:1 or lower.